The Billie System

Guy DempsterOur return to this unique fibre recovery mill in Hong Kong, five years after our first collaboration.

The Billie System is located inside Tai Po industrial estate– an enclave of streets up in Hong Kong’s New Territories, with Tolo Harbour to the south and the lush, subtropical Pat Sin Leng mountains rearing up to the north.

This kind of setting is quintessential Hong Kong and has always been one of my favourite aspects of the city– despite its dense, dizzying urbanity, you’re never far from nature. Around 75% of the region is undeveloped natural land– much of which is under statutory protection. This is one of the key reasons the buildings are so famously tall: if you can’t spread out, your only option is to build skywards.

Otis and I first visited The Billie System shortly after it opened in 2018. The operation fills a single floor of a low-rise commercial building, and we were immediately struck by its modest size and resource-lite approach to fibre recovery.

On this most recent visit, we were joined by some collaborators: the Foong sisters from iconic Newcastle slow fashion label High Tea with Mrs Woo (whose production offcuts we've previously recycled into yarn), and Professor Doris Li, a seamless knitting expert from the University of Technology Sydney. We all rendezvoused at Tai Po train station before fuelling up on Dim Sum and then cabbing it to The Billie.

The Billie practices a method of textile recycling called mechanical fibre recovery, which relies on a sequence of milling machines to churn and rend waste fabrics apart, yielding loose fibre which can then be spun back into yarn.

This is one of the two most common ways textiles are recycled at industrial scale, the other being chemical recycling – where fibres are essentially dissolved and then wet spun back into a type of rayon yarn.

Although material circularity feels like a very modern conversation, mechanical fibre recovery actually predates the advent of petrochemical fibres like polyester and nylon, and even rayon, by a good century. The practice originated in Yorkshire in the early 1800s to recover spinnable wool from old rags, in response to a national virgin wool shortage caused by the Napoleonic Wars, which raged across continental Europe.

The practice has been refined and gone in and out of vogue in the interim, but over the years, subsequent recovery systems have evolved to contend with cotton and more diverse fibres, and working with The Billie System we’ve been able to recover wool, cotton, bast fibres like linen and hemp, and even silk.

However, it’s important to note that The Billie System’s approach is especially unique. By integrating new automations and sanitisation practices, they’ve eliminated water and all liquid chemicals from the recycling process, and accordingly their mill produces no chemical waste– a rare feat in an industry notorious for thirsty and chemically intensive milling.

Our tour was led by Billie team members Andy Wong and Julie Wilkens, who walked us through the key areas of the facility. We began with the Ozone sanitisation system– their first key enhancement. Ozone gas sanitisation is an alternative to traditional laundering with water and detergents. Ozone is a synthetic gas that has a stringent, sterilising effect. You more often see it used as a modern alternative to chlorine to keep pools clean – pumped through the water in a poolside filter.

It’s created by electrifying oxygen in an on-site generator, causing the composing O₂ atoms to separate and then reconfigure into groups of three (O₃). Upon arrival at The Billie, textile waste is placed in large vats that are sealed and blasted full of ozone, sterilising all contents. The ozone is then plumbed out of the vats and released into the air outside, where it immediately dissipates – turning back into regular oxygen.

Next we moved through the disassembly workroom where trims, bulky seams, buttons and zippers are removed by hand– the most laborious part of the whole process, but essential prep work for feeding textiles into the automated systems, where any stray piece of metal or rigid hardware could gum up the whole operation.

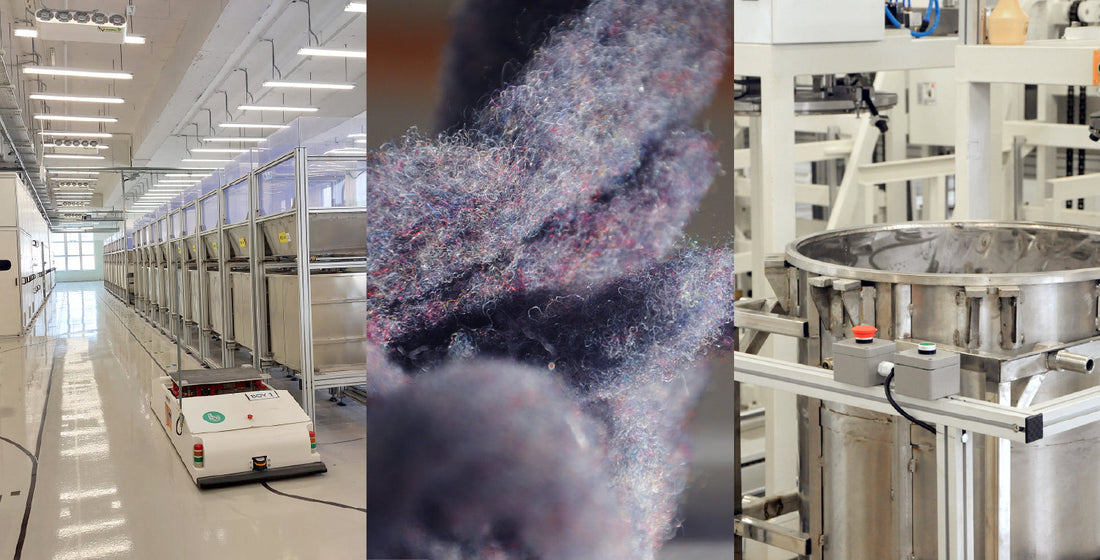

The next station is the colour sorter. To eliminate the need for bleaching or dyeing to create coloured yarns, textile waste is instead fed through an automated colour sortation system. The system can differentiate between nine different colour categories– using an optical sensor to detect a waste item’s colour as it travels along a conveyor belt, before a blast of air shunts it into a corresponding colour bin. The unique hue of the resulting recovered fibre (and the yarn it’s spun into) is therefore determined entirely by the colour of the textile waste that was recycled, and how these items have been colour sorted; no water, bleach, dyestuff, fixatives or mordants required.

And finally, we reached the fibre recovery machinery, which itself was near impossible to film– housed in an enclosed chamber to prevent fibre fluff from flooding the workspace. It grinds and churns waste fabrics, separating and teasing out their composing fibres. What emerges out the back of the machine is a gossamer-thin web of recovered fibre, which is gathered and wound into a thick rope-like sliver, ready for the next stage.

The Billie System fulfills these initial steps of the recycling process before trucking the recovered fibre to their subsidiary spinning mill to complete the next steps: blending, roving and spinning.

This mill is operated by Novetex Textiles, and is located in Zhuhai, Guangdong Province – about a two-hour drive west of Hong Kong. In fact, it was my previous work with Novetex that gave us the inroad to connect with The Billie.

I first encountering Novetex yarns while working as an assistant designer for a Sydney knitwear label between degrees. I was impressed by their early adoption of ethical and environmental certification for their cottons and wools – still a pretty novel move back in the early 2010s.

A few years later I was nearing the end of my knitwear and knitted textiles degree at Nottingham Trent in the UK, and was offered a position with Novetex in Hong Kong through the uni's professional placement service, which included periodic visits to their spinning facilities in Zhuhai. I scored the role and moved to Hong Kong, working and continuing my studies remotely through The Hong Kong Design Institute/IVE.

After crash-landing back in Australia in 2016, the news eventually reached me that Novetex was making plans to establish their own textile waste recovery facility; the first textile mill to open in Hong Kong in 50 years. Otis and I jumped on a plane back to Hong Kong soon after to check it out.

The Billie System is very much the brainchild of Novetex chairwoman Ronna Chao, granddaughter of famed entrepreneur Chao Kuang-Piu (K.P. Chao). Born in Shanghai, K.P. Chao relocated to Hong Kong in 1950 and went on to establish Novetex Woollen Mills in the 1970s. The Billie feels like the next big push to align their milling practices with a more circular vision for the industry, and I’m still astounded at their willingness to take the risk and build it. The system was built with an investment of about HK$15 million (≈ USD 1.9 million), and was co-developed with the Hong Kong Research Institute of Textiles and Apparel.

Beyond The Billie System, I know of several mills around the world that have mechanical fibre recovery capacities: The New Denim Project in Guatemala, Kipas Textiles in Türkiye, Camira Fabrics in the UK, our own Waverley Mills in Tasmania, De Martini Bayart & Textifibra (DBT) in Biella, and several in Prato, Italy – which has been a hub of wool recovery for over a century.

It’s a practice that’s garnering interest and gaining momentum globally, but what sets The Billie System apart is the way they’ve reimagined the entire recovery process as an interconnected whole.

They’ve designed laterally to consider every stage– from sanitisation to colour planning and fibre processing– to massively minimise resource use. If only this same level of temperance and careful coordination applied to every stage of a product's lifecycle.

At the end of our visit, our group decided to walk back to the MTR station. The route followed the curve of Tolo Harbour, giving us a chance to decompress and talk through everything we’d just seen. As we walked, we found ourselves wondering aloud: might a mill like this ever be seen in Australia? What would it take– politically, logistically, culturally– to support fibre recovery infrastructure of this kind onshore?

The Billie System demonstrates that it is possible to approach recycling, waste and resource reduction not as afterthoughts, but as primary design principles enforced at every stage of production (and ideally, at every stage of a product's life thereafter). It also reminds me of the immense value of small, focused innovations and risk–takers who are willing to pioneer new pracitces– giving us all a glimpse of how the industry could evolve.